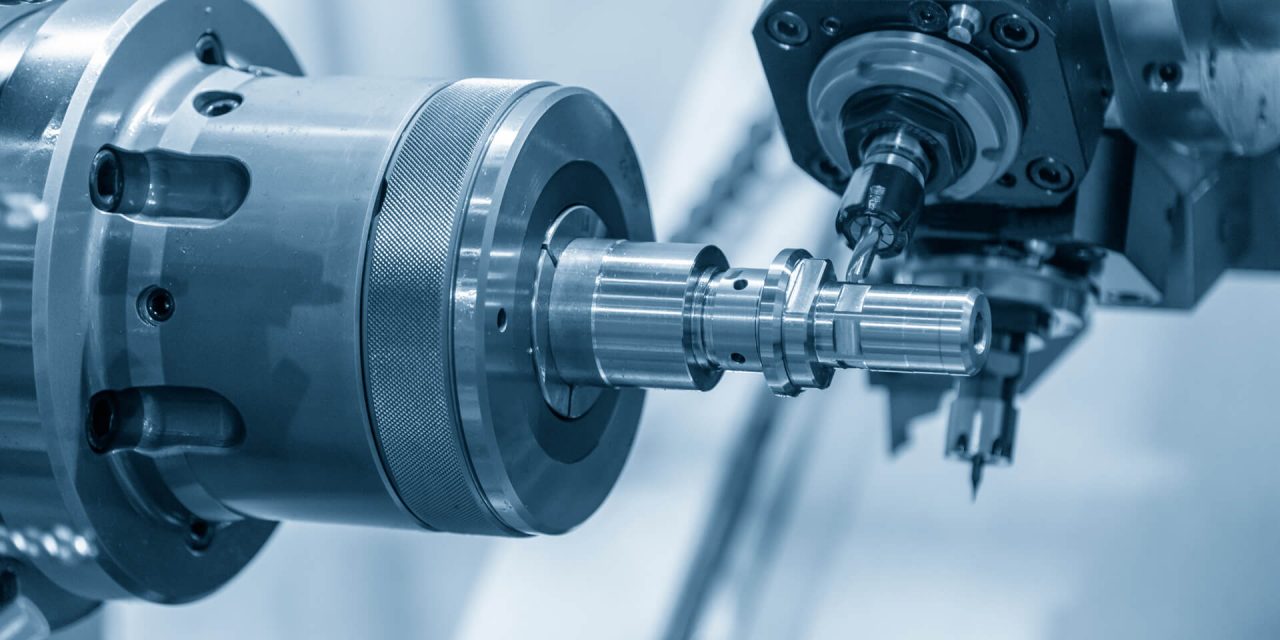

Customized Industrial Automation

Machinery, Software and hardware

We handle the entire cycle of our customized industrialized automation solutions, from situation analysis to design, production and testing, and to finish, assistance and maintenance. Machining centers, laser machines, CNC machines, robots, PLC, CNC and HMI software, artificial vision systems, panels and machine boards. Each element is perfectly integrated into an efficient project, in communication with existing plants and information systems. We find automated solutions for factory production, for logistics and selection in the warehouse, for laboratory tests

Applyca industrial automation is consulting, design, manufacturing

Consulting

Our skills are our strength, they are the reason why those who turn to Applyca require a wide-range of professional advice. The initial analysis of the situation and business objectives allows us to frame and break down the requests into individual elements to identify the most correct industrial automation solution in terms of effectiveness, efficiency, compliance with deadlines, safety and sustainability.

Design

We create mechanical and electrical designs,take care of pneumatic and hydraulic parts, program PLC, CNC and HMI software, customized applications and communication protocols. In doing so, we are committed to finding efficient solutions in the present and for the future that are easy to maintain and built to last.

Manufacturing

The manufacturing of the solutions identified takes place in our facility, whether they are entire machining centers, individual machines or just applications. This way, Applyca guarantees their proper functioning and we can test every detail, from the mechanical parts, to the software components, to the correct communication with all the devices necessary for the designed system.