Client: Nadir, Pordenone

Nadir is a company from Vigonovo di Fontanafredda (Pordenone) that specializes in the processing of aluminum, and brass parts. A company that designs and produces aluminum shapes and components for furniture, in particular for the bathroom and kitchen. In order to do this, it uses numerically controlled machines and modern robots.

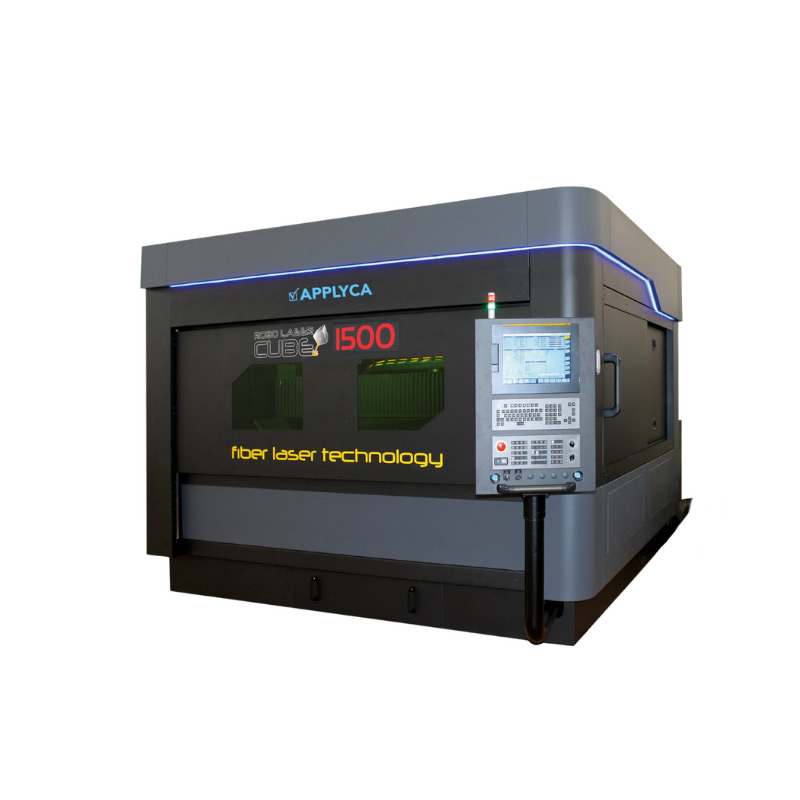

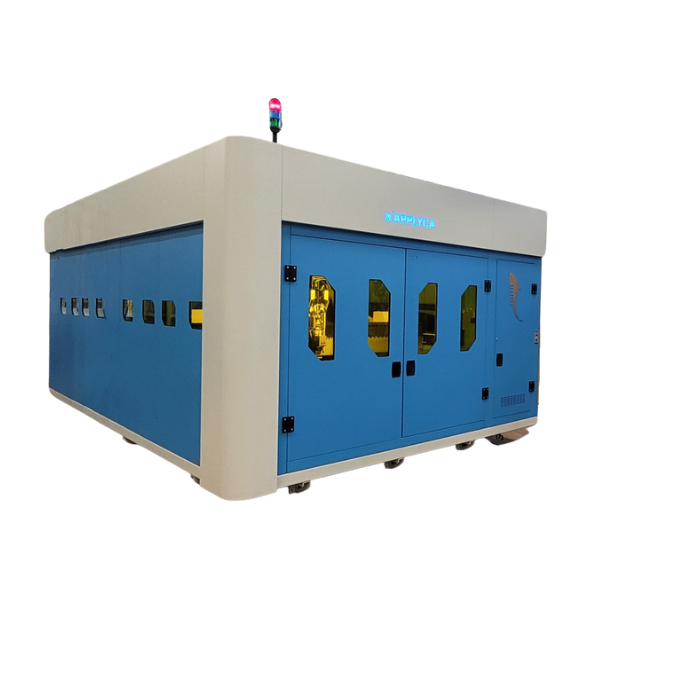

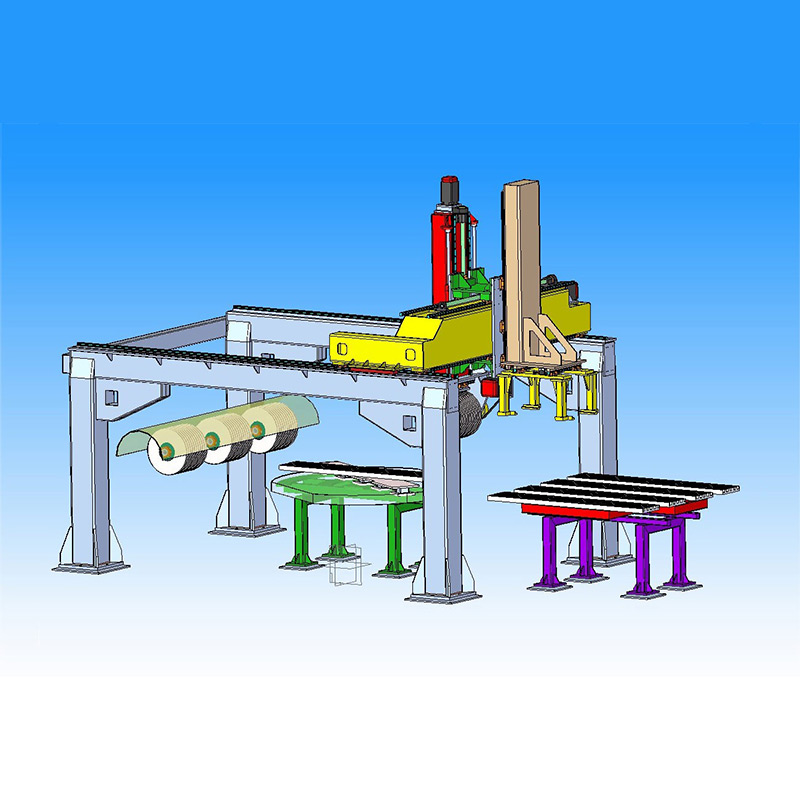

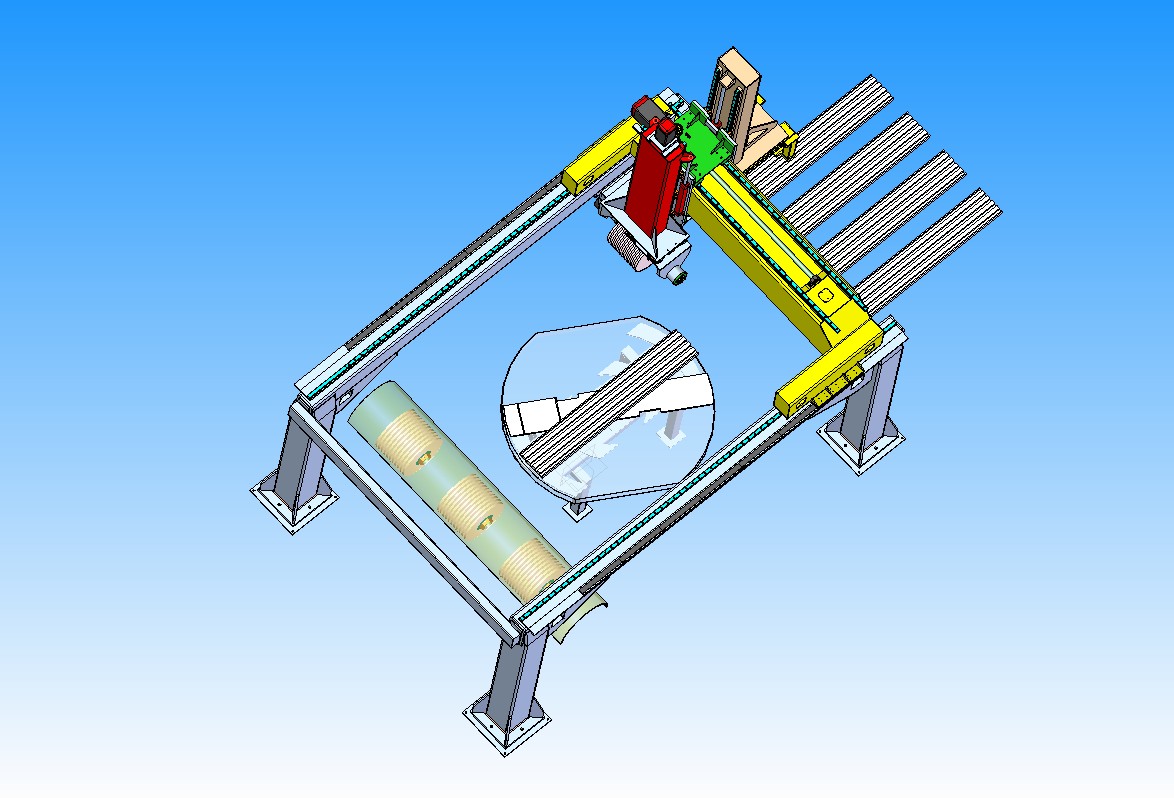

Brushing machine for aluminum furnishing elements. Automatic management of wear and brush changes without repositioning the pieces. Patented.

Request

Nadir is a small company that stands out for the accuracy of their work and reliability. They turned to Applyca because the external polishing process was often unsatisfactory for the high standards chosen and not strictly controllable. The decision was to internalize this final phase of production and to request advice for the construction of a customized automatic machine tool given the impossibility of satisfying the desired level of performance with the proposals available on the market. The brushing machine obtained was patented by Nadir.

Applyca’s Solution

The proposed consultation quickly turned into an order to design and build the customized automatic brushing machine. The flawless and long-lasting polishing of the metal parts for bathroom furniture components was achieved with brushes. A laser sensor was also introduced to constantly check the normal wear of the brushes and indicate the correct time for their replacement. To complete this phase, the automatic change of the brushes have been programmed, both in the case of wear (replacement and elimination) and in the case of polishing to be done with brushes with different characteristics, therefore without the need to reposition the piece.

This finished project by Applyca stirs questions, and we know it.

Customer data

- Project

- automatic brushing machine

- Applyca’s Service

- consulting, design and production of customized automation, application software, diagram and electrical panel creation

- Customer’s Sector

- aluminum processing for furniture production

- Place

- Vigonovo di Fontanafredda (Pordenone)

- Year

- 2015