Client: Stark, Udine

STARK S.p.A. resides in a town in the province of Udine (northeast of Italy) from 1962 to present, it has become a world leader in the metal cutting sector and one of the largest manufacturers of woodworking tools, particularly, circular blades, with branches located Worldwide.

Client’s request:

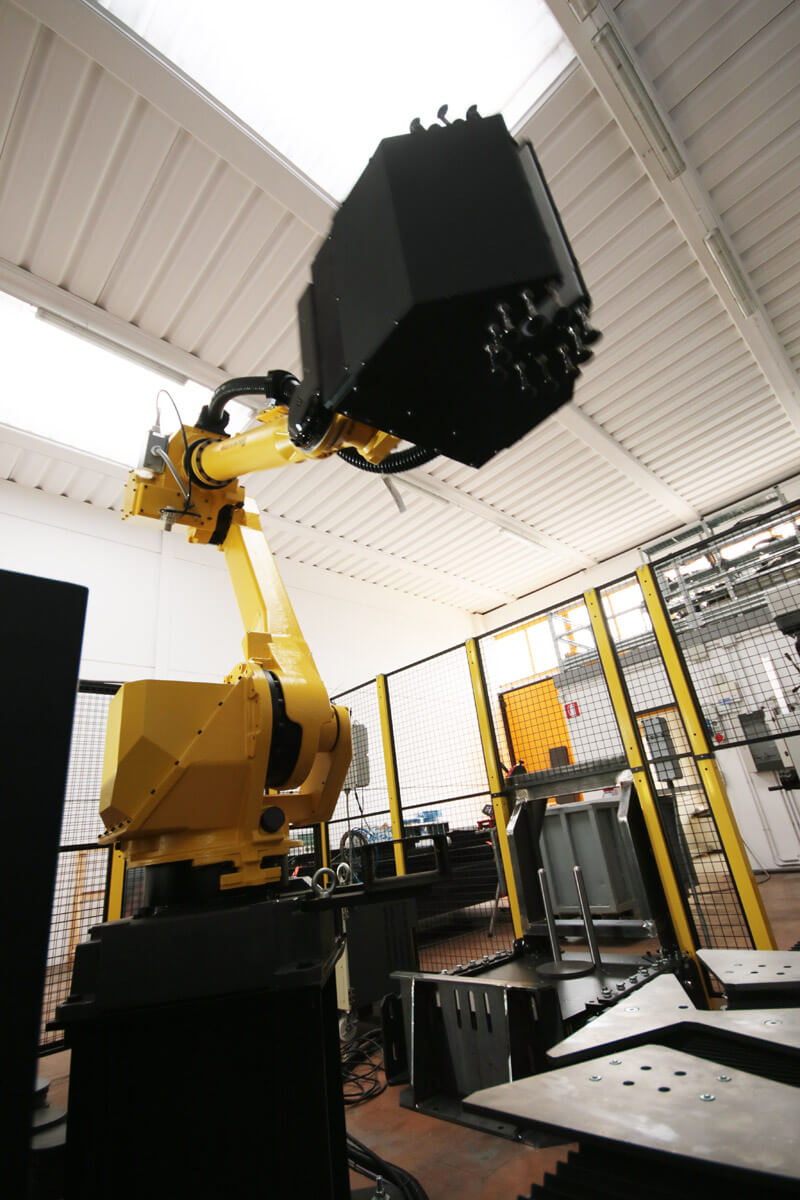

Stark’s staff were interested in our Robo Laser Cube because they saw how it guarantees a highly efficient, fast and precise cut, that are all essential requirements in the production field of metal cutting tools.

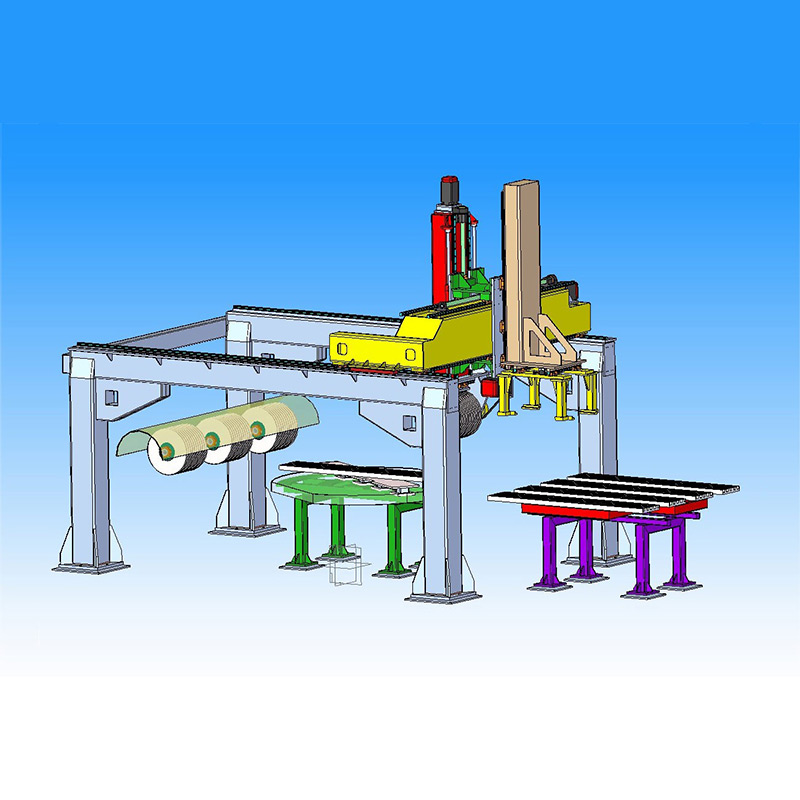

They chose to start with the Robo Laser Cube base to obtain a robotic system for customized sheet metal cutting personalized with:

- Laser source to cut all steels of which the circular blades are made.

- A personalized solution for maneuvering the blades robotically.

- A vision system capable of identifying the position and orientation of the drag holes, the arbor hole and possibly making additional holes in customized positions, thus generating Stark circular saw blades.

Applyca’s Solution

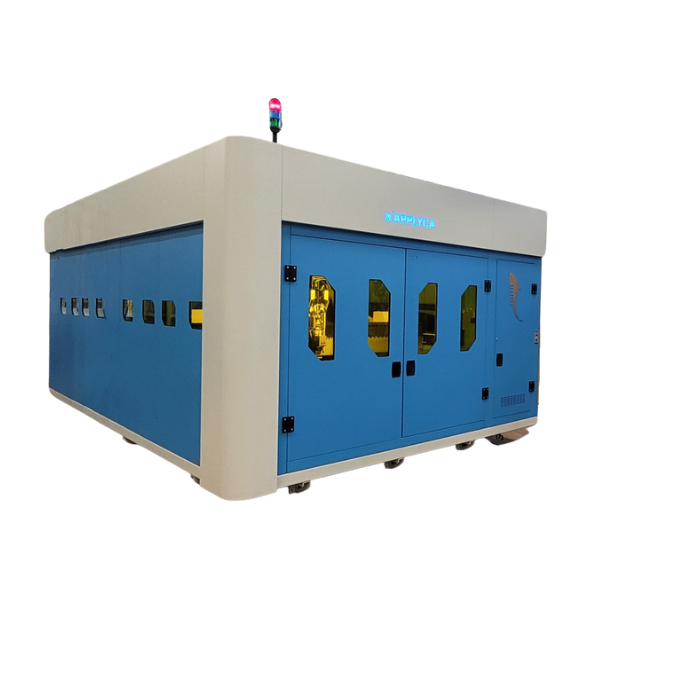

We have customized our Robo Laser Cube in a flat sheet metal cutting work cell using fiber laser technology with a vision system to move the cut blades. We proudly relied on the previously gained experience by personalizing our machines for major multinationals in the tooling world and drew on the technical, electrical and mechanical characteristics now consolidated in Applyca.

This Robo laser Cube is dedicated to cutting sheet metal of various sizes with a working range of 1,500×1,500 mm, making it easy to implement in small production spaces. The assembled components are of high quality; in this case, the CNC, made by Fanuc, and the electromechanical components by Siemens.

Our Customized Robo Laser Cube two-dimensional laser cutting machine. It produces the driving holes and the central hole of the Stark saw blades with an ad-hoc handling system.

Is this an Applyca solution that meets your needs?

Customer data

- The project

- Robotic system for sheet metal cutting

- Applyca’s services

- consultation, design and production of a personalized automation machine, projected vision system, diagram and electrical panel

- Client’s Sector

- Metal cutting and woodworking tools

- Place

- Trivignano Udinese (Udine)

- Year

- 2021